Flexible polyurethane foam, commonly known as foam or foam rubber, is a versatile material with a wide range of applications. It is used in various industries, from furniture manufacturing to automotive, aerospace, and even soundproofing solutions. The innovative potential of flexible polyurethane foam lies in its unique properties and ability to adapt to different needs and requirements.

Comfort and Cushioning

One of the most common and well-known uses of flexible polyurethane foam is in the production of cushioned seats and mattresses. The foam provides comfort and support, contouring to the body's shape and relieving pressure points. This makes it an ideal choice for cushions, pillows, and upholstered furniture. The high resiliency of the foam ensures that it retains its shape and allows for long-lasting comfort.

Additionally, flexible polyurethane foam can be designed to have different firmness levels, from soft and plush to firm and supportive. This allows manufacturers to create products tailored to individual comfort preferences, ensuring a personalized experience for the end-user.

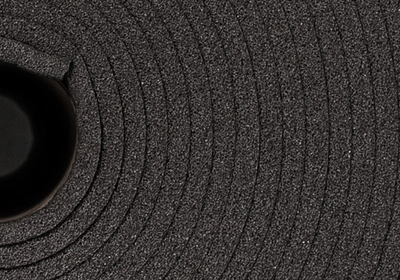

Insulation and Soundproofing

Another innovative application of flexible polyurethane foam is in the field of insulation and soundproofing. The foam's cellular structure and ability to absorb and dampen vibrations make it an excellent material for reducing noise transmission. It can be used in walls, floors, ceilings, and other structural elements to create quieter environments.

Traditionally, materials like fiberglass and mineral wool have been used for insulation and soundproofing. However, flexible polyurethane foam offers several advantages over these materials. It is lightweight, easy to install, and more effective at blocking airborne and impact noises. It also has excellent thermal insulation properties, helping to regulate temperature and reduce energy consumption.

Durability and Longevity

Flexible polyurethane foam is known for its durability and longevity. The material is resistant to wear and tear, making it suitable for high-traffic applications. It can withstand repeated use without losing its shape or support, ensuring the longevity of products like furniture, mattresses, and automotive seating.

Furthermore, the foam can be treated with additives and coatings to enhance its resistance to moisture, chemicals, and fire. This makes it a reliable and safe choice for various industries where durability and safety are essential.

Customization and Design Flexibility

One of the key advantages of flexible polyurethane foam is its ability to be customized and molded to specific shapes and designs. Manufacturers can create foam products with different densities, thicknesses, and sizes to meet the unique requirements of their applications. The foam can also be easily cut, carved, and shaped, allowing for intricate and customized designs.

This customization and design flexibility open up a world of possibilities in terms of product innovation. From unique furniture designs to specialized automotive interiors, flexible polyurethane foam can be tailored to meet the aesthetic and functional needs of various industries.

Sustainability and Eco-Friendliness

As the demand for sustainable materials increases, the foam industry has been exploring eco-friendly alternatives for flexible polyurethane foam. Manufacturers are developing foam products using renewable and bio-based materials, such as soybean oil and castor oil. These bio-based foams offer similar performance characteristics while reducing reliance on fossil fuels and minimizing environmental impact.

Additionally, efforts are being made to improve the recyclability of flexible polyurethane foam. New technologies and processes are being developed to recycle and repurpose foam waste, reducing the amount of foam ending up in landfills.

Conclusion

Flexible polyurethane foam has revolutionized various industries with its innovative potential. From providing comfort and cushioning in furniture and bedding to offering insulation and soundproofing solutions, the foam's versatility and unique properties have made it a go-to material for many applications. As the industry continues to evolve, there are exciting opportunities for further innovation and improvement in the world of flexible polyurethane foam.